Factory Introduction

Sunrise Foundry is a professional Metal Foundry, located in Ningbo.

We have been producing Gray Iron,

Ductile Iron Castings and and any other precision castings for more

than 25 years.

We are dedicated to meet different requirements of various

customers across the world, products are mainly

involved Agricultural and Construction Machinery, Hydraulic, Mining

industry, Municipal Products, some steel

and stainless steel castings for Pumps and Valves, Pipe Fittings,

etc.

Please feel free to contact us if you have any requests.

Products We’ve Made

We divide our products into several categories. Gray Iron Casting,

Ductile Iron Casting, Steel Casting, Stainless

Steel Casting for Scaffolding Accessories, Post Tension

Anchorage, Automotive Part, Pump and Valve Body,

Pipe Fitting, Manhole Cover and Bollard, Ornamental Fence and

Spear, Light Pole and Bench Casting, Railway Part.

Our Capability

We have updated our production line. Our production process include

Resin Sand Molding Line, Shell Molding Line,

Wet Green Sand Casting and Lost Wax Investment Casting Production

Process.

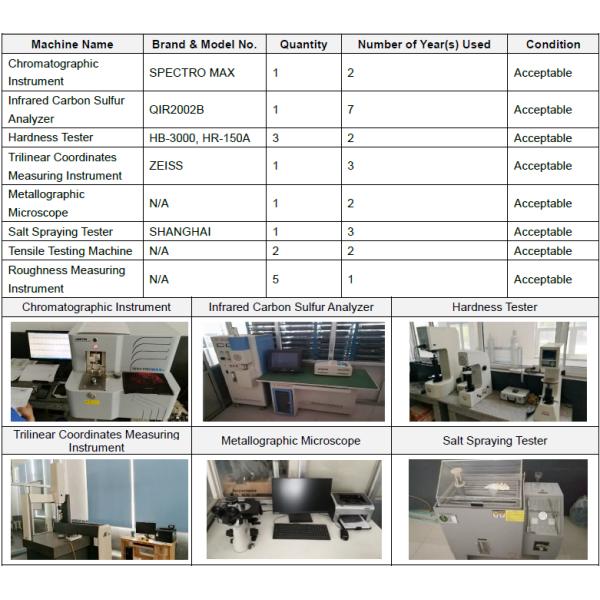

Quality Control

Quality Control is one of the most important process in production.

We insist that 100% inspection before

shipment and ensure parts without any flaws when sending out.

We have complete quality inspection facilities including mechanical

testing, chemical analysis, tensile strength,

hardness, spectrometer, ultrasonic testing, etc.

Certification